Signup for Free Breaking Email & SMS Alerts

Subscribe to our mailing list to receive news releases and other materials related to First Atlantic Nickel Corp.. Your email will never be shared or sold and you can opt out at any time.

Make sure you don't miss any important updates - Subscribe to our mailing list to be the first to receive news releases and other materials related to First Atlantic Nickel Corp.

Get In TouchHave a question for investor relations? Reach out to us at ir@fanickel.com or by phone at +1 (844) 592-6337.

Vancouver, British Columbia – (GlobeNewsWire – March 19, 2025) -- First Atlantic Nickel Corp. (TSXV: FAN) (OTCQB: FANCF) (FSE: P21) ("First Atlantic" or the "Company") is pleased to announce a strategic research partnership with Colorado School of Mines to explore geologic hydrogen as an energy source. This collaboration will focus on two significant ophiolite complexes in Newfoundland, Canada: the St. Anthony Ophiolite Complex (Atlantis Project, 103 km²) and the Pipestone Ophiolite Complex (Atlantic Nickel Project, 71 km²). Both projects are 100% owned by First Atlantic and encompass extensive ultramafic rock formations, characterized by awaruite-bearing serpentinized peridotites, which are key indicators of geologic hydrogen.

First Atlantic Nickel continues to advance its core operations focusing on exploring and drilling for awaruite nickel-iron alloy mineralization, which can be processed without smelting to create a secure, reliable supply of nickel for North America while reducing dependence on foreign nations for processing. This approach directly strengthens the resilience of North America's critical minerals supply chain. While maintaining this primary focus, the Company has established a strategic research partnership with Colorado School of Mines that leverages existing drilling data and exploration results from its Newfoundland ophiolite projects. The exploration data provided to Colorado School of Mines will support academic research on geological hydrogen as a potential energy source, with the ability to realize additional value from the project.

Geologic Hydrogen: Ophiolites and Peridotite

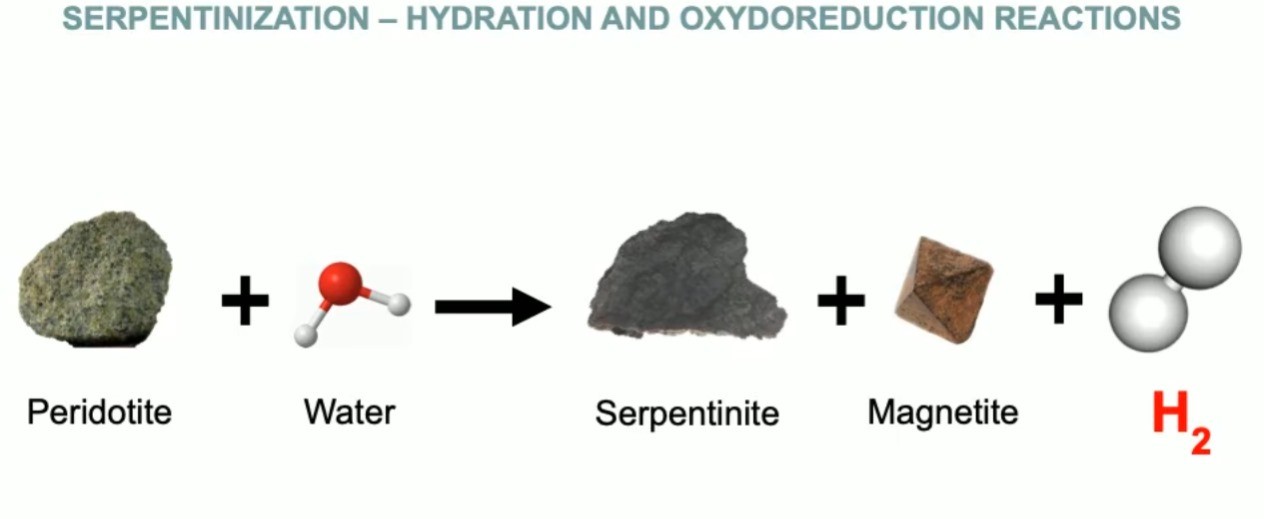

Ophiolites—sections of oceanic crust and upper mantle thrust onto continental crust—are globally recognized as prime sources of geologic hydrogen, often referred to as "white hydrogen" or "gold hydrogen." These formations are dominated by ultramafic rocks, notably peridotite, which consists primarily of olivine and pyroxene minerals rich in nickel, chromium, magnesium, and iron. When peridotite interacts with water, it triggers serpentinization—a hydrothermal reaction in which iron oxidizes and water is reduced, releasing molecular hydrogen gas (H₂). This natural process can be represented by the equation:

3FeO (in olivine) + H₂O → Fe₃O₄ (magnetite) + H₂ (hydrogen gas)

During serpentinization, awaruite (Ni₃Fe) forms as a secondary mineral when liberated nickel (Ni2+) and iron (Fe2+) from the olivine, pyroxene, and chromite minerals react with the abundant hydrogen (H2) present. This natural process can be represented by the equation:

3Ni²⁺ + Fe²⁺ + 4H₂ → Ni₃Fe (awaruite) + 8H⁺

The formation of awaruite could not happen without the presence of abundant hydrogen. This process occurs readily in ophiolitic peridotites at depth, where water saturated rocks in oxygen-poor, reducing conditions produce this exothermic reaction, generating heat that sustains further reactions. According to the Geological Survey of Finland, "In Europe and in regions outside the crystal shield, only ophiolites are often referred to as a source of geological hydrogen."[1] Within these ophiolite settings, serpentinized peridotites are the most promising targets, with peridotites producing significantly more hydrogen than other rocks. As stated in a Frontiers in Geochemistry article, "The best targets for stimulated hydrogen production are rocks such as peridotites, which can produce 2–4 kg hydrogen/m³ of rock, up to 4-orders of magnitude more hydrogen than mafic rocks such as basalts."[2] Ophiolites represent large potential sources of geologic hydrogen, with some of the most significant global geologic hydrogen discoveries occurring in ophiolites.

Figure 1: Visual representation of the serpentinization process forming hydrogen

Quote From Dr. Yaoguo Li, Colorado School of Mines

“Geologic hydrogen systems are a combination of mineral systems and natural gas systems. In our group, we have the unique combination of expertise from both the mining industry and oil and gas industry to advance geologic hydrogen exploration and stimulated hydrogen monitoring” said Dr. Yaoguo Li from Colorado School of Mines.

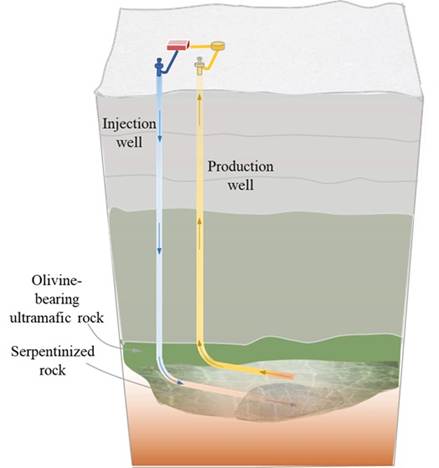

Figure 2: Conceptual example of Geologic Hydrogen Extraction wells targeting serpentinized ultra mafic rocks, process involves a process similar to fracking, stimulating, and hydrogen recovery.[3]

Awaruite: Indicator of Hydrogen-Producing Conditions

Academic research has established awaruite (Ni₃Fe) as a reliable indicator mineral for hydrogen-rich geological environments. A landmark 2004 study published in the Proceedings of the National Academy of Sciences (PNAS) documented:

"Metamorphic hydration and oxidation of ultramafic rocks produces serpentinites, composed of serpentine group minerals and varying amounts of brucite, magnetite, and/or FeNi alloys. These minerals buffer metamorphic fluids to extremely reducing conditions that are capable of producing hydrogen gas. Awaruite, FeNi₃, forms early in this process when the serpentinite minerals are Fe-rich.”[4]

The PNAS researchers also noted: "The partial pressure of H2 needed to form awaruite increases with temperature. For example, at 200°C, awaruite of composition FeNi3 cannot form unless the H2 partial pressure is more than ≈320 bars, which would preclude awaruite formation in a shallow land system. Even at low temperature, partial pressures in excess of 50 bars H2 is needed to form awaruite."[5]

This established scientific understanding makes awaruite an excellent indicator of hydrogen-rich environments, as it forms only under the highly reducing conditions created by significant hydrogen generation. The distribution of awaruite within serpentinized peridotites in Newfoundland's ophiolites underscores the region's promise for this research.

Newfoundland's Ophiolite Complexes: Pipestone & St Anthony’s Ophiolite Complexes

The research will focus on two properties wholly owned by First Atlantic hosting major ophiolite complexes:

Atlantis Project (St. Anthony Ophiolite Complex)

Located in northwestern Newfoundland, the St. Anthony Ophiolite Complex spans 103 km² across two ultramafic massifs (60 km² and 43 km²). This flat-lying, thrusted sequence of oceanic lithosphere includes a mantle section dominated by serpentinized harzburgite and dunite—peridotite subtypes rich in olivine. Historical exploration identified nickel and chromium mineralization, with recent surveys confirming the presence of awaruite in serpentinized zones. The complex's shallow structural orientation facilitates surface access to potential hydrogen-producing formations, making it an ideal study site.

Atlantic Nickel Project (Pipestone Ophiolite Complex)

Covering 71 km², this project features a 30 km long ultramafic belt within the Pipestone Ophiolite Complex. Unlike the Atlantis Project, the Pipestone Ophiolite exhibits a steep to near-vertical dip, suggesting a depth extent exceeding several kilometers. First Atlantic Nickel recently reported a new discovery at the RPM Zone, intersecting 0.24% Nickel and 0.32% Chromium over 383.1 meters of serpentinized peridotite hosting disseminated awaruite, with no cutoff in mineralization depth, indicating continuity of hydrogen-producing environment. The complex's deep structure aligns with models of hydrogen retention, where lithostatic pressure at depths beyond 1 km could trap gas within zones of low permeability.

Global Hydrogen Ophiolite Discoveries

The research will draw insights from significant hydrogen-producing ophiolites worldwide:

Samail Ophiolite (Oman)

This formation produces hydrogen through low-temperature water/rock reactions, with dissolved H₂ concentrations as high as 2.9 millimolar in peridotite wells. Research estimates hydrogen generation at depths up to 5 km, with some hydrogen trapped and some escaping via springs, providing a benchmark for retention dynamics. Studies suggest that for economically viable extraction, stimulation methods must increase hydrogen production rates by at least 10,000-fold over natural levels[6]—a challenge being explored through enhanced fracturing and fluid chemistry adjustments.

Bulqizë Mine (Albania)

This recently discovered hydrogen reservoir vents a minimum of 200 tons of hydrogen annually at 84% hydrogen by volume[7], making it one of the largest recorded hydrogen flows globally. The hydrogen originates from a faulted reservoir deeply rooted in the Jurassic ophiolite massif, suggesting similar potential for similar ophiolite systems like those in Newfoundland.

Hydrogen Retention and Extraction Potential

When hydrogen forms during serpentinization, it may be contained if the surrounding rock has low permeability. The serpentinization process often reduces permeability, potentially self-sealing the system. At increasing depths, lithostatic pressure can exceed gas pressure, aiding containment. Extraction methods under exploration include conventional drilling techniques similar to those used in the oil and gas industry. For the Atlantis Project, in-ground stimulation methods similar to hydraulic fracturing are being evaluated to enhance hydrogen production from its accessible, flat-lying peridotite. Conversely, the deep-extending vertical structures at the Atlantic Nickel Project may host natural hydrogen reservoirs potentially accessible through targeted deep drilling.

Technical-economic analysis suggests that for economically viable hydrogen production from engineered water-rock reactions in peridotite formations, stimulation methods must increase net hydrogen production at least 10,000-fold compared to natural rates[8]. Researchers propose achieving this through increased fracturing density and optimizing the chemistry of injected fluids to enhance hydrogen generation.

Figure 3: Illustration of geophysics needed in stimulated H2. Real-time monitoring of H2 generation process using integration of electromagnetic and magnetic data: characterizing and monitoring the temperature field, and real-time feedback to engineering operation using ML processing. (Image courtesy Mengli Zhang and Jenny Crawford.)

Multidisciplinary Research Methodology

The Company’s partnership with Colorado School of Mines will employ a comprehensive suite of techniques to evaluate hydrogen potential:

These integrated methods aim to construct a 3D model of hydrogen distribution, pinpointing high-potential zones for further exploration or stimulation.

Technical Expertise from Colorado School of Mines

Colorado School of Mines has 150 years of history in mineral exploration, the Department of Geophysics has 100 years of history in mineral exploration, and the collaborating group Center for Gravity, Electrical, and Magnetic Studies (CGEM) has history of 25 years of continuous research in this space funded by mineral and oil & gas industries. CGEM currently has geologic research projects funded by Advanced Research Projects Agency–Energy (ARPA-E) and by industry. They bring world-class expertise in geologic hydrogen systems, with an established track record of collaboration with industry leaders in the mineral industry and oil and gas industry. Their proficiency in geologic hydrogen research, geophysical modeling and remote sensing will enhance the project's ability to characterize hydrogen reservoirs at depth.

ABOUT COLORADO SCHOOL OF MINES

Colorado School of Mines is a public R1 research university focused on applied science and engineering, producing the talent, knowledge and innovations to serve industry and benefit society – all to create a more prosperous future.

Scientific and Economic Implications

Geologic hydrogen represents a potentially significant, low-cost, and sustainable energy resource that could substantially complement existing energy systems. Dr. Mengli Zhang from Colorado School of Mines has located more than 500 drilled natural gas wells using geophysics and followed through with post-drilling analyses. Dr. Zhang commented, “Through these experiences, I have developed expertise in prospecting maps of geologic hydrogen and drilling location recommendations. Our group brings a unique set of expertise to the full cycle of geologic hydrogen exploration.”

Unlike traditional hydrogen production methods that require significant energy inputs, naturally occurring hydrogen from ophiolites is continuously generated by ongoing geological processes and may be trapped in large reservoirs. This natural production pathway could result in substantially lower costs compared to conventional hydrogen manufacturing processes.

The research program has three primary goals: first, to discover and map potential geologic hydrogen resources within Newfoundland's ophiolite complexes; second, to develop exploration techniques for these resources; and third, to establish efficient hydrogen generation methodologies from serpentinized ultramafic rocks. Geologic hydrogen has the potential to be a large-scale source of hydrogen that is cheaper and safer than traditional methods of hydrogen production that rely on oil and gas.

Awaruite (Nickel-iron alloy Ni₂Fe, Ni₃Fe)

Awaruite, a naturally occurring sulfur-free nickel-iron alloy composed of Ni₃Fe or Ni₂Fe with approximately ~75% nickel content, offers a proven and environmentally safe solution to enhance the resilience and security of North America's domestic critical minerals supply chain. Unlike conventional nickel sources, awaruite can be processed into high-grade concentrates exceeding 60% nickel content through magnetic processing and simple floatation without the need for smelting, roasting, or high-pressure acid leaching[9]. Beginning in 2025, the US Inflation Reduction Act's (IRA) $7,500 electric vehicle (EV) tax credit mandates that eligible clean vehicles must not contain any critical minerals processed by foreign entities of concern (FEOC)[10]. These entities include Russia and China, which currently dominate the global nickel smelting industry. Awaruite's smelter-free processing approach could potentially help North American electric vehicle manufacturers meet the IRA's stringent critical mineral requirements and reduce dependence on FEOCs for nickel processing.

The U.S. Geological Survey (USGS) highlighted awaruite's potential, stating, "The development of awaruite deposits in other parts of Canada may help alleviate any prolonged shortage of nickel concentrate. Awaruite, a natural iron-nickel alloy, is much easier to concentrate than pentlandite, the principal sulfide of nickel"[11]. Awaruite's unique properties enable cleaner and safer processing compared to conventional sulfide and laterite nickel sources, which often involve smelting, roasting, or high-pressure acid leaching that can release toxic sulfur dioxide, generate hazardous waste, and lead to acid mine drainage. Awaruite's simpler processing, facilitated by its amenability to magnetic processing and lack of sulfur, eliminates these harmful methods, reducing greenhouse gas emissions and risks associated with toxic chemical release, addressing concerns about the large carbon footprint and toxic emissions linked to nickel refining.

Figure 4: Quote from USGS on Awaruite Deposits in Canada

The development of awaruite resources is crucial, given China's control in the global nickel market. Chinese companies refine and smelt 68% to 80% of the world's nickel[12] and control an estimated 84% of Indonesia's nickel output, the largest worldwide supply[13]. Awaruite is a cleaner source of nickel that reduces dependence on foreign processing controlled by China, leading to a more secure and reliable supply for North America's stainless steel and electric vehicle industries.

Investor Information

The Company's common shares trade on the TSX Venture Exchange under the symbol "FAN", the American OTCQB Exchange under the symbol “FANCF” and on several German exchanges, including Frankfurt and Tradegate, under the symbol "P21".

Investors can get updates about First Atlantic by signing up to receive news via email and SMS text at www.fanickel.com. Stay connected and learn more by following us on these social media platforms:

https://x.com/FirstAtlanticNi

https://www.facebook.com/firstatlanticnickel

https://www.linkedin.com/company/firstatlanticnickel/

FOR MORE INFORMATION:

First Atlantic Investor Relations

Robert Guzman

Tel: +1 844 592 6337

rob@fanickel.com

Disclosure

Adrian Smith, P.Geo., is a qualified person as defined by NI 43-101. The qualified person is a member in good standing of the Professional Engineers and Geoscientists Newfoundland and Labrador (PEGNL) and is a registered professional geoscientist (P.Geo.). Mr. Smith has reviewed and approved the technical information disclosed herein.

About First Atlantic Nickel Corp.

First Atlantic Nickel Corp. (TSXV: FAN) (OTCQB: FANCF) (FSE: P21) is a Canadian mineral exploration company developing the 100%-owned Atlantic Nickel Project, a large-scale nickel project strategically located near existing infrastructure in Newfoundland, Canada. The Project's nickel occurs as awaruite, a natural nickel-iron alloy containing approximately 75% nickel with no-sulfur and no-sulfides. Awaruite's properties allow for smelter-free magnetic separation and concentration, which could strengthen North America's critical minerals supply chain by reducing foreign dependence on nickel smelting. This aligns with new US Electric Vehicle US IRA requirements, which stipulate that beginning in 2025, an eligible clean vehicle may not contain any critical minerals processed by a FEOC (Foreign Entities Of Concern)[14].

First Atlantic aims to be a key input of a secure and reliable North American critical minerals supply chain for the stainless steel and electric vehicle industries in the USA and Canada. The company is positioned to meet the growing demand for responsibly sourced nickel that complies with the critical mineral requirements for eligible clean vehicles under the US IRA. With its commitment to responsible practices and experienced team, First Atlantic is poised to contribute significantly to the nickel industry's future, supporting the transition to a cleaner energy landscape. This mission gained importance when the US added nickel to its critical minerals list in 2022, recognizing it as a non-fuel mineral essential to economic and national security with a supply chain vulnerable to disruption.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Forward-looking statements:

This news release may include "forward-looking information" under applicable Canadian securities legislation. Such forward-looking information reflects management's current beliefs and are based on a number of estimates and/or assumptions made by and information currently available to the Company that, while considered reasonable, are subject to known and unknown risks, uncertainties, and other factors that may cause the actual results and future events to differ materially from those expressed or implied by such forward-looking information. Forward looking information in this news release includes, but is not limited to, expectations regarding the timing, scope, and results from the Phase 1 work and drilling program; results from the Phase 2 work and drilling program, future project developments, the Company’s objectives, goals or future plans, statements, and estimates of market conditions. Readers are cautioned that such forward-looking information are neither promises nor guarantees and are subject to known and unknown risks and uncertainties including, but not limited to, general business, economic, competitive, political and social uncertainties, uncertain and volatile equity and capital markets, lack of available capital, actual results of exploration activities, environmental risks, future prices of base and other metals, operating risks, accidents, labour issues, delays in obtaining governmental approvals and permits, and other risks in the mining industry. Additional factors and risks including various risk factors discussed in the Company’s disclosure documents which can be found under the Company’s profile on http://www.sedarplus.ca. Should one or more of these risks or uncertainties materialize, or should assumptions underlying the forward-looking statements prove incorrect, actual results may vary materially from those described herein as intended, planned, anticipated, believed, estimated or expected.

The Company is presently an exploration stage company. Exploration is highly speculative in nature, involves many risks, requires substantial expenditures, and may not result in the discovery of mineral deposits that can be mined profitably. Furthermore, the Company currently has no reserves on any of its properties. As a result, there can be no assurance that such forward-looking statements will prove to be accurate, and actual results and future events could differ materially from those anticipated in such statements.

[1] https://www.gtk.fi/en/current/geology-in-the-hydrogen-era/

[2] https://www.frontiersin.org/journals/geochemistry/articles/10.3389/fgeoc.2024.1366268/full

[3] https://research.lbl.gov/2024/06/26/geologic-hydrogen-a-new-source-of-carbon-free-fuel-for-the-world-new-opportunities-for-the-lab/

[4] https://www.pnas.org/doi/10.1073/pnas.0405289101

[5] https://www.pnas.org/doi/10.1073/pnas.0405289101

[6] https://www.frontiersin.org/journals/geochemistry/articles/10.3389/fgeoc.2024.1366268/full

[7] https://www.science.org/doi/10.1126/science.adk9099

[8] https://www.frontiersin.org/journals/geochemistry/articles/10.3389/fgeoc.2024.1366268/full

[11] https://d9-wret.s3.us-west-2.amazonaws.com/assets/palladium/production/mineral-pubs/nickel/mcs-2012-nicke.pdf

[13] https://www.airuniversity.af.edu/JIPA/Display/Article/3703867/the-rise-of-great-mineral-powers/